Considered one of the “classic” grinding processes, double-disk grinding is performed when both sides of a workpiece must be ground so that both surfaces are exactly plane and parallel. The workpiece is not fixed for this process. Instead, it is loosely placed in the “nest” of the workpiece carrier. Then both sides of the workpiece are simultaneously machined between two grinding wheels. The upper grinding wheel is adjusted with the “tilt” navigation setting, which allows the upper wheel to maintain the desired angle with the lower wheel. Thus, the gap between the grinding wheels is greater on the infeed side than on the outfeed, resulting in the required amount of stock removal.

当工件的两面均需磨削以形成平面且相互平行时,可采用被认为是“经典”磨削工艺之一的双端面磨削。在该过程中,工件是不受固定的,而是直接放到工件载体的“巢”中,在两个磨轮之间同时对工件的两面进行加工。上磨轮采用“倾斜”导向设置进行调整,可以与下磨轮保持所需角度。因此,磨轮之间的间隙在横切侧要大于出料侧,以满足所需的磨削量。

Through regular dressing, the grinding wheels maintain their form and sharpness.

通过定期修整,可使磨轮保持其形状和锋利度。

Up to 40% cost savings

最多可节省40%的成本

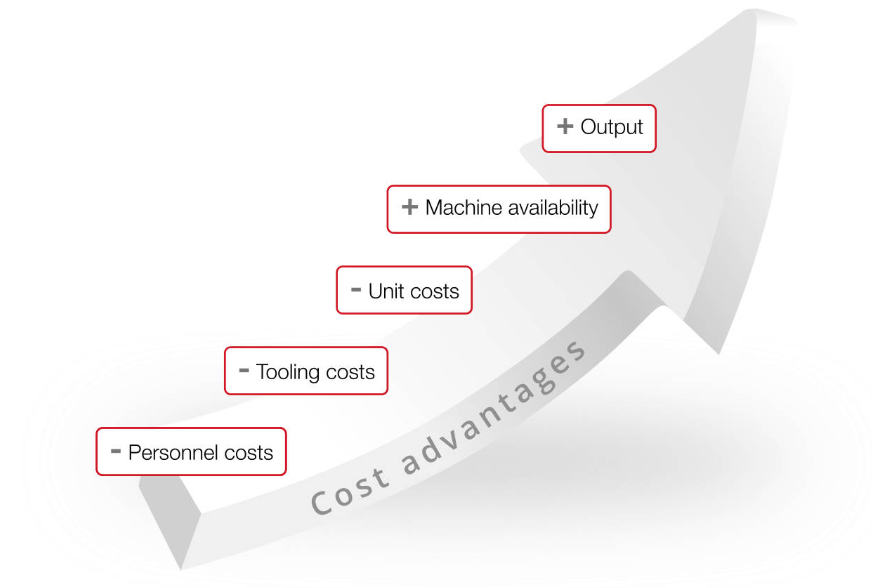

The latest generation of Supfina's Planet V machine series takes double disk grinding, also known as discus grinding, to a new level. In addition to the patented tilt navigation and visualization of the grinding process, the main focus is on SDC (Smart Dressing Cycle) with up to 40% cost savings compared to conventional systems.

Supfina最新一代Planet V系列机床的问世,将双端面磨削(又称双盘磨削)提升到全新水平。除了获得专利的倾斜导航和磨削过程可视化之外,该系列的主要亮点在于,与传统的系统相比,SDC(智能修整循环)可将成本降低40%。

Did you know? The SDC can also be retrofitted to existing Planet V series machines. The cost of the retrofit pales in comparison to the savings that will be achieved.

您知道吗?SDC系统还可改装到现有的Planet V系列机床上。与将要节约的成本相比,改装的成本可忽略不计。

The extremely rigid machine bed enables grinding of steel, sintered metal, non-ferrous metal, plastics, ceramics and glass. Two powerful motors, depending on the tool configuration and material, achieve stock removal rates of over 1mm with cycle times well below one second. In just one pass, the workpiece is machined with an average tolerance of plus/minus 0.003mm.

极其坚硬的机床床身可以磨削钢铁、烧结金属、有色金属、塑料、陶瓷和玻璃。根据刀具配置和材料的不同,两个强大的马达可实现超过1毫米的去料率,而周期时间远低于1秒。仅需一次加工,工件的平均公差就能达到正负0.003毫米。

Planet V - The Series

Detail oriented

Planet V 系列机床

注重细节

The vertical spindle arrangement offers the user the highest resulting workpiece qualities while reducing piece costs.

垂直主轴的排列为用户实现最高的工件质量,同时降低工件成本。

Unique features include the Smart Dressing Cycle, the patented grinding gap visualization and the integrated tool change aid. This reduces downtime as tool changes and retooling operations are kept to a minimum.

独特的功能包括智能修整循环,已获专利的磨削间隙可视化和集成砂轮更换辅助系统。因为将刀具更换和修磨操作控制在最低限度,所以减少了停机时间。

Due to its space-saving design, Planet V machines can be easily integrated into new or existing production lines.

Planet V系列机床的外观设计节省空间,可以轻松地整合到现有生产线中。

- Smart Dressing Cycle SDC

- Grinding Gap Visualization System

- Patented Tilt Navigation TNS

- In-Process Measurement

- Smaller Footprint

- Extremely Rigid Machine Base

- 智能化修磨循环SDC系统

- 磨削间隙可视化系统

- 获得专利的磨盘倾斜导航TNS

- 在线测量

- 占地面积小

- 极其坚固的床身

Flexible processes

灵活的工艺

In addition to classic throughfeed grinding, Supfina's Planet V machine series offers other process options. Pendulum grinding offers max. uniform thickness by oscillating in the grinding gap and can prevent a further fine grinding process in some applications. Another process option is multiple pass grinding, where the components are passed through the grinding gap multiple times. This process helps you to realize the stock removal without additional handling in case of high stock removal.

除了经典的贯通式研磨外,Supfina的Planet V系列机器还可提供其他工艺选择。摆式研磨能通过在研磨间隙中的摆动实现最大均匀厚度,在某些应用中可以防止过度精细研磨。另一类工艺是多道研磨,即部件多次通过研磨间隙。该工艺可在去除量大的情况下,无需额外处理,就能实现毛坯的去除。

Solutions from a single source

单一来源的解决方案

As a solution provider, Supfina does not start with machine development and production, but advises interested parties and customers on their individual challenges, validates quality parameters and even conducts its own studies to develop the appropriate machining solution. Subsequent integration into existing production structures is taken into account, as is the of future-proof automation and IT infrastructure.

作为解决方案的提供者,Supfina并不从机器的开发和生产下手,而是向感兴趣的各方和客户提供定制建议以帮助他们应对挑战,验证质量参数,甚至自行研究开发合适的加工方案。同时也会考虑后续将新工艺与现有生产结构相整合,以及与面向未来的自动化和IT基础设施相整合。

In particular, the automation of loading and unloading through to robot-assisted process automation is currently a strong focus of demand. "Our customers are increasingly demanding sophisticated systems for their production processes," explains Dominik Maier, business unit manager, "whether complex automation or upstream and downstream processing, we deliver the solution."

需要特别注意的是,装载和卸载的自动化,直至机器人辅助的流程自动化,是目前需求的主要焦点。"我们的客户越来越需要复杂的系统来满足他们的生产流程,"业务部经理Dominik Maier说到,"无论是复杂的自动化还是上下游加工,我们都能提供解决方案。"

From maintenance to production and process support to individual training, a comprehensive, modern range of services is available.

从维护到生产和工艺支持,再到个人培训,我们都可以提供全面且现代化的系列服务。

Source: https://www.supfina.com/en/products-en/machines/double-disk-grinding.html