薛佳 女士

| 电话 | +86 21 63232733 |

|---|---|

| 传真 | +86 21 63232733 |

| 邮箱 | katelyn.xue@hjtexpo.com |

| 地址 | 上海市黄浦区广东路500号世界贸易大厦5层 |

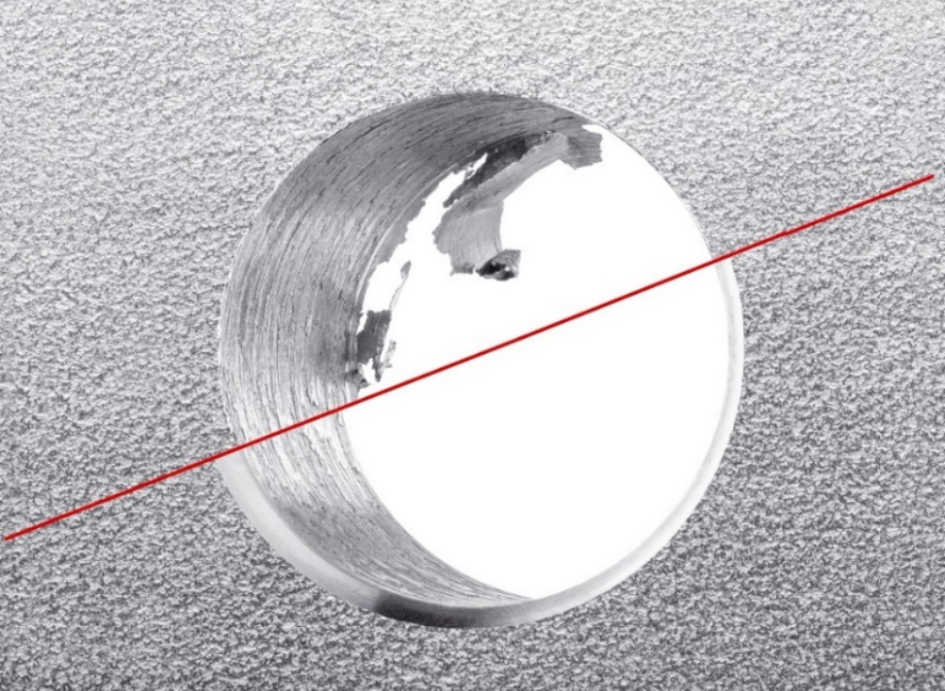

由于孔口毛刺在运行过程中会造成重大问题,通常必须去除

Burrs at hole openings usually need to be removed due to significant problems caused by them during operation.

批量生产或要求较高的应用需要可靠的加工过程。如果孔加工中产生了毛刺,那么找到一个快速而可靠的去毛刺工艺尤为重要。但是哪一种去毛刺工艺是正确的选择呢?本报告概述了最常见的去刺孔方法以及它们的优缺点。

Batch production or high-demand applications require reliable processing. If burrs are generated during hole machining, finding an efficient and reliable deburring process becomes particularly important. But which deburring process is the right choice? This report outlines the most common methods for deburring holes and their advantages and disadvantages.

在汽车、飞机或流体动力等行业,制造过程不断被优化,以尽可能高效、低成本地实现批量生产。简化工艺步骤,降低节拍,减少重复加工,并提高质量。对生产经理来说,孔口毛刺非常头疼,他们面临着找到快速、廉价、可靠的去毛刺解决方案的挑战。

In such industries as automotive, aerospace, or fluid power, the manufacturing process is constantly being optimized to achieve mass production with high efficiency and low cost. Simplifying process steps, reducing cycle times, minimizing redundant machining, and improving quality are the key objectives. For production managers, burrs at hole openings can be a big headache, as they need to tackle the challenge of finding a fast, cost-effective, and reliable deburring solution.

适用不同应用的去毛刺工艺

Deburring Processes Suitable for Different Applications

选择去毛刺方法的重要标准是毛刺在工件上的位置、所使用的材料和工件的制造公差。所需的去毛刺结果、生产工艺的兼容性、机器能力和预算也会影响去毛刺解决方案的选择。最常见的去毛刺方法及其特点如下所示。

The selection of deburring methods should be based on the burr's location, the materials, and the manufacturing tolerances. Besides, the desired deburring performance, compatibility with the production process, machine capabilities, and budget should also be taken into account. The most common deburring methods and their characteristics are as follows:

Thermal Energy Method (TEM) deburrs materials with high-temperature evaporation caused by chemical reactions. TEM is particularly suitable for holes with complex geometries and hard to reach, or workpieces with multiple holes. It can remove both internal and external burrs at the same time. Almost all oxide materials can be deburred by TEM, resulting in a sharp or slightly rounded hole. However, the size of the reaction chamber limits the workpiece size and quantity of parts. And the impact of high temperatures on the material and dimensions of the parts should be considered.

Electrochemical Machining (ECM) deburrs by electrochemically dissolving metal. It can be used for almost all metals, including hardened workpieces. As it is a non-contact technique with very low heat input, there is no tool wear, no formation of secondary burrs, and no mechanical impact. The maximum deburring size is about 0.3 millimeters. Thorough cleaning of the workpiece is required before and after the process.

High-Pressure Waterjet Deburring (HDW) can remove burrs from multiple hole openings and hard-to-reach holes simultaneously. Water jets at pressures of up to 1000 bar are directed onto the parts requiring deburring. After deburring, it is necessary to inspect the hole openings to ensure complete removal and to verify if the surface of the workpiece is still rough due to any remaining burr roots.

When using sandblasting deburring method, materials such as sand are directly sprayed into the hole openings at a speed of up to 80 m/s. As the surfaces around the hole openings are also affected, the cleaning work after deburring can be challenging.

Brush deburring involves using special brushes to remove burrs. Due to the availability of various brush forms, deburring with brushes is a simple and widely applicable method. The disadvantage of brush deburring is its inability to remove large burrs, handle hard materials, and reach difficult-to-access holes.

Mechanical deburring tools allow the workpiece to undergo all deburring process at the machining center. Backside machining of holes and deburring of specific curved shapes can also be achieved. This technology offers repeatability and high process-reliability. However, the mechanical deburring method has its limitations when deburring hard-to-reach holes.

机械去毛刺解决方案提供一致的去毛刺结果

Mechanical deburring solutions offer consistent deburring results.

尽管存在制造公差,但去毛刺简单

Despite the manufacturing tolerances, deburring is a straightforward process.

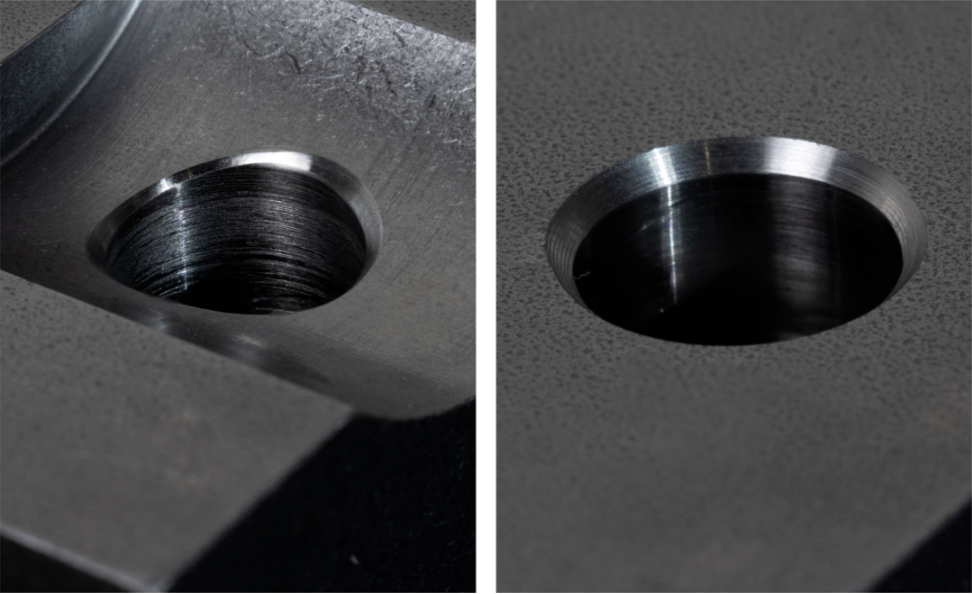

机械去毛刺的技术具有多种形式,这就是为什么我们要仔细研究不同机械去毛刺技术的特点。在插补铣去毛刺中,刀具根据预定的加工路径进行切削。由于制造或装夹公差的存在,倒角可能太大,太小,或者甚至根本没有倒角。

Mechanical deburring technologies come in various forms, which is why it is important to thoroughly study the features of each of them. In interpolation milling deburring, the tool cuts based on a predetermined machining path. Due to the manufacturing or clamping tolerances, there may be too big, to small, or even no chamfers.

带有浮动刀片的刀具只有接触到孔口之后才会开始去毛刺。这样,具有公差变化的工件,例如铸件,也可以可靠地加工,并具有一致的去毛刺结果。对于所有机械去毛刺方法,最大的优点是它可以集成到现有的加工中心。工件的去毛刺只需稍微增加一些节拍,不再需要额外的去毛刺步骤。

Tools with floating blades only start deburring after contacting the hole opening, which allows reliable processing of casts and other workpieces with tolerance variations, ensuring consistent deburring performance. The greatest advantage of all mechanical deburring methods is their integration into existing machining centers. The deburring process only takes a little more cycle time, without the need for separate deburring steps.

通过减少清洗、物流或外部加工成本,降低了整体工艺成本和节拍。由于生产技术一致,工具操作简单,不需要对人员进行培训。因此,现有的加工资源和知识能够得到最大化利用。

Overall process costs and cycle times can be reduced by lowering down the cleaning, logistics, or external processing costs. With consistent production technology and simple tools, there is no need for personnel training. Therefore, existing machining resources and expertise can be maximized.

带有浮动刀片的机械去毛刺解决方案

HEULE好优利公司的COFA工具

直接在机床上完成工件的去毛刺和交付

Mechanical deburring with floating blades

HEULE's COFA tool

Finishing the deburring and delivering steps all together on the machine

特殊应用解决方案的可能性

The Possibilities of Solutions to Special Applications

一旦生产经理决定了去毛刺的方法,找到合适的类型和合适的合作伙伴是很重要的。如:一家电动汽车制造商需要在转子轴上完成内部难以进入的冷却孔的去毛刺。此前,去毛刺都是手工完成的。由于客户因质量偏差而提出的投诉,每年大约有100万个孔,必须找到一个更稳定和自动化的去毛刺工艺。

Once a production manager has decided on the deburring method, it is crucial to find the right type and suitable partner. For example, previously, when an electric car manufacturer needed to deburr internal cooling holes on rotor shafts that were difficult to access, they had to finish that manually. And approximately one million holes per year would be complained by customers due to quality variations. Therefore, a more stable and automatic deburring process is highly needed.

在这种去毛刺的情况下,由于部件的壁厚不同,因此内主孔的直径也各有不同。由于这些公差的变化,插补铣去毛刺并不是一个好的选择。

In this situation, the diameters of the internal main holes vary due to differences in the component's wall thickness. And considering these tolerance variations, interpolation milling deburring is not a good choice.

在一次展会上,生产经理开始了解到HEULE好优利刀具品牌,及其带有浮动刀片的去毛刺工具。采用X-BORES去毛刺技术后,客户很快认可了HEULE好优利刀具的去毛刺的质量。之前负责手工去毛刺的员工已在其他工位工作。

At an exhibition, after knowing about the HEULE brand and its deburring tools with floating blades, a production manager decided to adopt the X-BORES deburring technology, and shortly obtained his customers’ positive feedbacks about the deburring performance of HEULE tools. The employees previously responsible for manual deburring were reassigned to other workstations.

与此同时,客户也联系了HEULE探索更多的应用,一个定制化的刀具解决方案正在开发中。如果在标准刀具品类中没有合适的工具,HEULE将针对特定应用需求提供定制化服务。HEULE建议所有客户,尽早让我们的去毛刺专家参与到设计阶段。与好优利一起,工件的几何形状可以优化为尽可能有利于去毛刺的形状,还可以优化操作前的毛刺的形成,从而使批量生产效率最大化。

Meanwhile, this customer also contacted HEULE to explore more applications, and a customized tooling solution is under development. If there are no suitable tools in the standard tooling catalog, HEULE will provide customized services tailored to specific application requirements. HEULE recommends all customers to involve our deburring experts in the design stage as early as possible. HEULE can optimize the workpiece to the most deburring-friendly shape, and minimize the formation of burrs before the operation, thereby maximizing efficiency in batch production.

为了更好的体验

请竖屏浏览